Automatic Water Shutoff for Bathtubs, Sinks and more.

Flowban Download Installation Instructions & Tech Sheet

Don't let Bathtub or Sink Overflows cause Thousands in Flood Damage

Stop Bathtub Overflowing

Flowban Automatically Stops Bathtubs from Overflowing. NO Electricity Needed to Operate & NO Maintenance.

Flowban Shuts off the water to the faucets, so bathtub & sinks overflows are a thing of the past.

It is a purely mechanical system that reacts when the water reaches a certain level in the Bathtub.

Stop Kitchen Sink Floods

Flowban Automatic Water Shutoff Valve Saves Water and Energy.

Even when a bathtub or sink doesn’t overflow it’s wasted on standard tubs & sinks overflow drains.

Flowban Automatically Shuts off the water before wasting water down the drain. Saving Water and the Energy that was used for your water heater.

Stop Bathroom Sink Overflows

It can also be used on certain types of Sinks, Washtubs, Basins, Residential & Commercial to stop Water Overflows.

Flooding from overflowing causes water damage that is very expensive to repair and if your insurance will cover it?

Flowban is an Insurance Policy against water overflow flood damage.

Flooding from overflowing baths causes water damage that is expensive to repair. In high rise properties such as Multi Family and Hotels just one flooding bathtub can cause massive damage to multiple units and rooms.

QUALITY ASSURANCE

Flowban is an insurance policy against tub flood damage. Maybe you will never need it but you can rest assured that a catastrophic tub flood event will never happen where a Flowban is installed.

There are many leak and flood detection devices that tell you there is already a flood, but only Flowban can stop flooding before it even starts. It uses no electrical sensors or a “memory” of normal flow and usage. It is a purely mechanical system that reacts when the water reaches a certain level in the tub. It resets itself automatically as soon as the faucets are turned off.

Watch how Flowban Stops Bathtub & Sink Overflows

Flowban is a simple solution to the Bathtubs & Sinks Overflowing problem. Invisible to the bath user, it requires no extra sensor to be fitted inside the tub and no electricity supply to operate. It is intuitively self-resetting and Maintenance FREE.

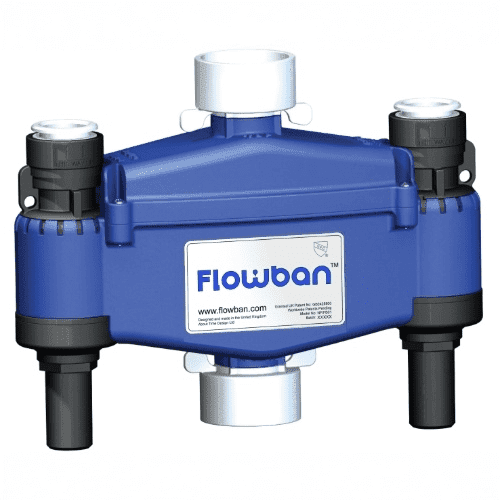

Flowban has been designed for easy installation using John Guest push fit connections. It must be located between the overflow outlet and the waste.

Faucets left unattended can result in bathtubs flooding which can cause expensive damage down multiple floors. Even if the overflow outlet can deal with the incoming water, something they often fail to do on jet tubs, the wasted water and the energy used to heat it is an unnecessary expense.

Faucets left running can easily be forgotten and within minutes the water can reach the overflow, a short time later it can be flooding the bathroom! Some people deliberately allow the faucets to keep running so they can continuously top up with hot water. This is very wasteful and can cause flooding as well.

As a Flowban Distributor for the US we can only sell one (1) Flowban unit online at a time. If you would like to purchase more than one (1) Flowban Please see our Bulk Buying & Pricing.

Stop Bathtubs & Sinks from Overflowing

Flowban is a simple solution to the problem. Invisible to the bath user, it requires no extra sensor to be fitted inside the tub and no power supply to operate. It is intuitively self re-setting and maintenance free.

Flowban has been designed for easy installation using John Guest push fit connections. It must be located between the overflow outlet and the waste. Flowban is connected to the overflow pipe between the outlet from the tub and the waste. The hot and cold pipes are connected to the supply ports either side of the float chamber.

When the water level in the bath reaches the overflow outlet, water enters the central chamber and activates the float. As the float rises, the magnets that are set into each end of the float react with the magnets on the flapper valves in the supply ports. The flapper valves are pushed into the water flow where the water pressure holds them in the closed position.

A trickle of water is allowed to bypass the flapper valve and out of the faucet. The trickle indicates the faucet is still open but the water level will drop and the central chamber drain. This allows the float to revert to its rest position, but the flapper valves stay closed, held in place by the water pressure.

Once the faucet is turned off, the pressure equalizes each side of the flapper valve which is then drawn back to the open position by the magnet on the float. The faucet can be turned on again and full waterflow will resume.

Flowban Automatic Water Shutoff Valve Stop Bathtub Overflows and flood damage to your home.